Shape memory alloys are metals that can shift from one predetermined shape to another depending on the temperature it is subjected to. It was discovered 60 years ago and has since been used in different fields, including biomedicine and aeronautical engineering. But it has continuously refused to harvest energy from hot water – something that is about to change.

The founders of a company called Exergyn said they have made an engine capable of generating electricity. Their machine uses morphing wire and hot water left over from industrial processes. The development of the engine has its roots in a backyard experiment conducted five years ago in Dublin.

After heating water in an electric tea maker, the founders – a scientist, an engineer, and a businessman – poured it into a bisected segment of pipe. At the bottom of that pipe lay a wire made of shape memory alloy, with one of the men holding a ruler next to it.

The men observed that the wire shortened by a couple of centimeters when hot water was poured through the pipe. When they poured cold water over the wire, its original length returned.

It is estimated that in the US about a third of the energy is lost as heat. Rigoberto Advincula, a waste-heat expert and professor of macromolecular science at Case Western University, said that lots of energy is wasted in industrial processes or during heat exchange, which happens when water is poured on machines to cool them off. The hot water produced as a result of industrial applications is not hot enough to produce steam capable of powering an engine in order to get a generator going.

There are a few power plants and others in the industrial industry who send hot waste water through secondary engines. These engines area able to convert a little amount of energy into electricity. The process for achieving that is called the organic Ranking cycle, but it needs chemicals in order to generate power from hot water.

Since some of the chemicals that need to be used are considered dangerous and harmful for the environment, they have been banned or their use is restricted. Although there are cleaner chemicals, they are not as efficient in creating energy from waste water. Plus, they create additional operational costs.

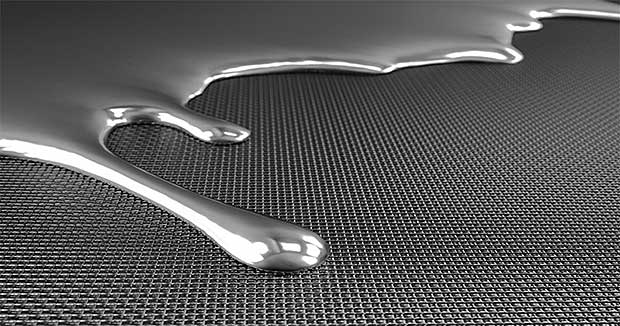

The answer, then, lies in morphing wires – the heart of what’s in the new engine created by Exergyn. The company’s engine uses nitinol, a shape metal alloy variation made of nickel (Ni) and titanium (Ti). The “nol” in its name refers to the former Naval Ordnance Laboratory where the alloy was invented.

The Exergyn engine takes advantage of nitinol’s shape-shifting behavior to convert hot water waste into electricity. Its makers say the engine could be used in a waste-heat plumbing system where hot water is cycled into piston chambers, each attached to a nitinol wire. The wire contracts when hit with hot water then expands when cold water rushes through.

A viscous fluid lies on the other side of the piston, which pushes the fluid through a hydraulic transmission which in turn spins a generator leading to electricity being created.

Exergyn isn’t claiming a breakthrough with their engine, but they used existing research to create nitriol. Just how much a company can save on electricity when they buy an Exergyn engine still remains to be seen. For now, a prototype sits in Exergyn’s own offices in Dublin with actual field tests scheduled to be carried out in 2018.

Exergyn CEO Alan Healy says that the trials will prove that there is a way to achieve energy efficiency. He says that unless businesses are given a money saving option, they won’t do the right thing.