Solar energy has improved over the years, but it’s far from perfect. Experts still need to find ways to increase the efficiency of solar cells and maximize their output. They also need to develop the technology that will make solar panels more affordable for ordinary consumers or at least justify their high upfront costs.

Materials science startup PLANT PV has come up with a solution to one of these problems through its new Silver-on-Aluminum Paste. Through this product, the company claims that solar cells will have increased power output without requiring manufacturers to make additional investments and deal with extra overhead costs.

How It Works

Currently, silicon solar cells are made by forming silicon ingots into wafers that are around 180 to 350 micrometers thin. An anti-reflective coating is then applied to each wafer to increase the amount of light that the cell obtains. The front surface is given a metal contact with a grid pattern by using a silver paste to screen-print small and large bars (called “fingers” and “bus bars”, respectively). The paste is then fired to create metal electrodes that have an electrical junction with the silicon surface.

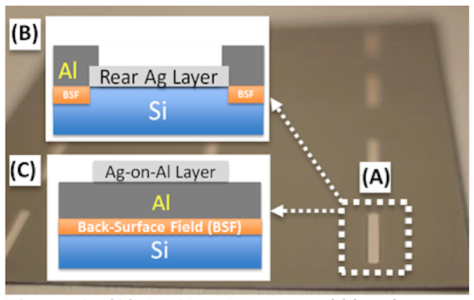

The back area, meanwhile, is given a full-metal contact using a metal paste. It’s designed in such a way that it has a rear tabbing layer, which means a silver layer is applied directly on the silicon surface. A smaller line of aluminum paste is on the sides, creating a back surface field (BSF) with the silicon surface. Since the silver layer takes up most of the space, rear tabbing layer prevents the full formation of the BSF and reduces the solar cell’s open-circuit voltage. This causes the cell to lose around 0.05 percent to 0.15 percent of efficiency.

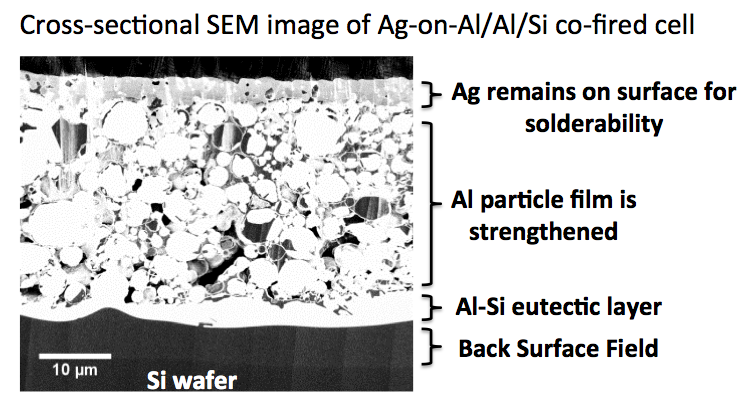

PLANT PV aims to change this with the Silver-on-Aluminum Paste, which can be printed directly on dried aluminum film. This changes the conventional rear tabbing layer design since the entire aluminum surface can now be entirely covered with aluminum paste. As a result, the cell will have a complete BSF along with the formation of a silicon-aluminum eutectic layer. The paste is also designed to strengthen the aluminum layer underneath while preventing silver/aluminum inter-diffusion during co-firing, which further increase the cell’s efficiency.

The power conversion efficiency of cells that are using the Silver-on-Aluminum Paste is the same as with full aluminum cells, but they increase open-circuit voltage by around 2 MV and raise the fill factor by approximately 0.2 percent. PLANT PV tested the paste in Fraunhofer ISE in Freiburg, Germany, and results showed that cells using the Silver-on-Aluminum paste exhibited an absolute efficiency gain of 0.15 percent over multi-crystalline silicon cells that were using conventional rear-tabbing pastes.

What Does This Mean for the Solar Energy Industry?

PLANT PV co-founder Dr. Craig Peters believes that the Silver-on-Aluminum paste will help address the problem of efficiency loss that comes from printing silver bus bars directly on solar cells’ silicon surface. If the 85-gigawatt global production for 2017 (which was forecast by GTM research) is fully implemented, Peters states that the new paste will “enable an estimated 500-MW more power to be developed by today’s PV module facilities”. This is a huge benefit to manufacturers (who won’t need to adopt new work processes) as well as to consumers (who will enjoy higher efficiency and bigger ROI).